The Dirty Dozen: 12 Common AV Installation Errors and How to Prevent Them with Better Workflow Automation

The High Stakes of Flawless AV Installation: Why Errors Aren't an Option

In the world of commercial Audio Visual (AV) integration, the installation phase is where the rubber meets the road. All the meticulous planning, design work, and client consultations culminate in the physical creation of a sophisticated AV system. However, this critical stage is also fraught with potential pitfalls. A seemingly minor oversight or error during installation can lead to a cascade of problems: system malfunctions, safety hazards, project delays, budget overruns, and ultimately, a damaged reputation. For AV integrators, minimizing installation errors isn’t just about quality control; it’s about protecting profitability, ensuring client satisfaction, and maintaining a competitive edge. While human error can never be entirely eliminated, many common AV installation mistakes are preventable with better processes, clearer communication, and the strategic use of workflow automation powered by specialized AV project management software. Let’s delve into twelve of these common culprits and explore how a more systematic approach can help you avoid them.

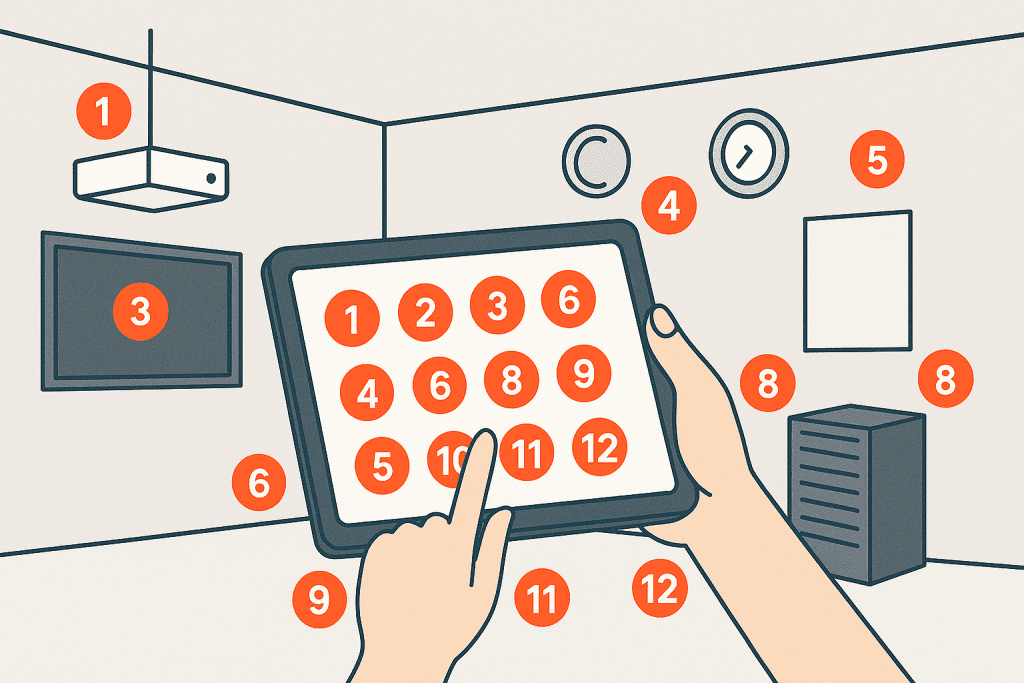

The Dirty Dozen: 12 Common AV Installation Errors That Plague Projects

Recognizing these common errors is the first step towards prevention:

- Inaccurate Site Survey Data Leading to Design Flaws: If the initial site survey is incomplete or inaccurate (e.g., wrong dimensions, missed obstructions, incorrect power/data locations), the design will be flawed, leading to inevitable installation problems when equipment doesn’t fit or integrate as planned.

- Poor Cable Management and Labeling: A rat’s nest of unlabeled cables is not only unsightly but also a nightmare for troubleshooting, maintenance, and future upgrades. Incorrect cable types or lengths can also degrade signal quality.

- Incorrect Equipment Mounting and Placement: Improperly mounted displays, projectors, or speakers can pose safety risks, offer poor viewing/listening experiences, or damage the equipment or building structure.

- Ignoring Environmental Factors: Failing to account for ambient light (for displays/projectors), acoustics (for audio systems), temperature, or ventilation for equipment racks can lead to suboptimal performance and reduced equipment lifespan.

- Insufficient Power or Network Infrastructure: Underestimating power requirements or providing inadequate network bandwidth/ports can cripple an AV system before it even goes live.

- Lack of Coordination with Other Trades: AV installation often happens alongside other construction or fit-out work. Poor coordination with electricians, HVAC technicians, or builders can lead to conflicts, damage, or delays.

- Misinterpreting Design Schematics or Plans: Complex AV designs can be misinterpreted by installation teams if the documentation isn’t crystal clear or if there’s a disconnect between the design office and the field.

- Skipping or Rushing System Testing and Commissioning: Thorough testing of every component and the system as a whole is crucial. Cutting corners here often means discovering problems after the client expects a working system.

- Inadequate Product Knowledge or Training: Technicians installing unfamiliar or highly complex equipment without proper training are more prone to making mistakes.

- Using Incorrect Tools or Fasteners: Employing the wrong tools for the job or using inappropriate fasteners for mounting can damage equipment or create unsafe installations.

- Failure to Document As-Installed Conditions: Not accurately documenting the final installation, including any deviations from the original plan, makes future servicing and upgrades incredibly difficult.

- Poor Communication & Lack of a Clear Snagging Process: When issues are identified (snags), a lack of a clear process for reporting, tracking, and resolving them can lead to them being overlooked or poorly addressed.

The Solution: Workflow Automation & Smart Project Management

Many of these errors stem from breakdowns in process, communication, or information management. This is where AV project management software with robust workflow automation capabilities can make a profound difference. By standardizing processes, ensuring information accuracy, and improving communication, you can systematically reduce the likelihood of these common installation mistakes.

How Workflow Automation Directly Addresses Installation Errors

- Standardized Checklists & Processes: Workflow automation allows you to implement mandatory digital checklists for every stage, from pre-installation site verification to final commissioning tests. This ensures no critical step is missed.

- Improved Information Flow & Accuracy: Automated workflows ensure that the correct, up-to-date information (e.g., design plans, site survey data, equipment lists) is accessible to the installation team when and where they need it.

- Enhanced Communication & Notifications: Automated alerts can notify team members of task assignments, dependencies, required approvals, or when issues are flagged, ensuring timely responses.

- Version Control for Documentation: Ensures that installers are always working from the latest approved design documents, reducing errors from outdated plans.

- Structured Snagging & Issue Resolution: Automated workflows can manage the snagging process, from reporting an issue with photos/notes to assigning it for resolution and tracking its completion.

Mastering the AV Change Order: Key Process Steps & Software Support

1. Formal Change Request Submission

Every requested change, no matter how small it seems, must be formally documented. This isn’t about being bureaucratic; it’s about ensuring clarity and accountability.

- Process: Establish a clear channel for clients or internal team members to submit change requests. This could be a dedicated email, a form, or ideally, a feature within your project management software.

- Software Support (e.g., Integrio): Look for software that offers a Form Builder or a dedicated change request module. Integrio’s Form Builder can be customized to create a standardized Change Request Form, ensuring all necessary information (description of change, reason, requestor, date) is captured consistently.

2. Impact Assessment (Time, Cost, Resources)

Once a change is requested, its potential impact on the project must be thoroughly evaluated.

- Process: The project manager, in consultation with the design and technical teams, needs to assess:

- Cost Implications: Additional hardware, software, licensing, and labor costs.

- Time Implications: How will the change affect the project schedule and key milestones?

- Resource Implications: Will additional team members or different skill sets be required?

- Technical Feasibility & Risk: Is the change technically sound? Does it introduce new risks?

- Software Support: Your AV project management software should allow you to easily access current project data (budgets, schedules, resource allocations) to inform this assessment. Tools that help in re-estimating or scenario planning are beneficial.

3. Client Communication & Approval

Transparency with the client is paramount. Present the impact assessment clearly and obtain formal approval before proceeding.

- Process: Create a formal Change Order document that details the requested change, its impact on cost and schedule, and any revised terms. This document should be sent to the client for their review and signature.

- Software Support (e.g., Integrio): Integrio’s Branded Documentation feature allows you to generate professional-looking Change Order documents. Integration with e-signature tools or a client portal for digital approvals can streamline this step significantly.

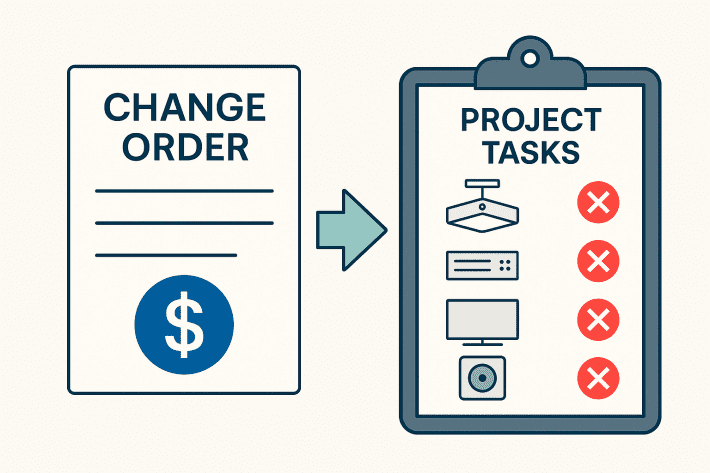

4. Updating the Project Plan & Documentation

Once a change order is approved, the master project plan, budget, schedule, and all relevant documentation must be updated to reflect the new scope.

- Process: This is a critical step often missed. The project manager needs to ensure that task lists, timelines, resource assignments, and design documents are all revised.

- Software Support: Good AV project management software will make this easier by allowing you to version control documents, update project baselines, and ensure that all team members are working from the latest information. Integrio’s centralized platform ensures that updates are reflected across the project.

5. Implementing the Change & Monitoring

With the plan updated, the approved change can be implemented. Progress should be monitored just like any other project task.

- Process: Assign tasks related to the change, track their progress, and manage any new dependencies.

- Software Support: Task management, scheduling, and progress tracking features within your AV project management software are key here. Integrio’s Workflow Automations can even help adjust schedules or notify relevant team members once a change order is approved and integrated.

Ready to see Integrio’s Product-to-Space Mapping in action?

Arrange a one-to-one demo and trial integration today free of charge.

Arrange a demo

Arrange a demo with an expert member of the team today

How Integrio.app Equips You to Conquer Scope Creep

Integrio.app is designed with the understanding that change is a part of AV projects. Our platform provides the integrated tools you need to manage scope creep effectively and protect your profitability:

- Customizable Form Builder: Create standardized Change Request Forms to ensure all necessary details are captured from the outset. No more vague requests via email or hallway conversations.

- Centralized Project Data: Easily access up-to-date project schedules, budgets, and resource information to accurately assess the impact of any proposed change.

- Professional Branded Documentation: Generate clear, professional Change Order documents for client review and approval, ensuring transparency and maintaining a record.

- Integrated Workflow Automations: Once a change order is approved, Integrio’s workflows can help automatically update relevant parts of the project plan, assign new tasks, or adjust timelines, minimizing manual administrative work.

- Version Control & Document Management: Keep track of all project documentation, including original scope documents and all approved change orders, ensuring everyone is working from the correct version.

- Seamless Field-to-Office Collaboration: Ensure that any changes to the plan are immediately communicated to field teams via the mobile app, preventing work based on outdated information.

Preventing the Dirty Dozen with Integrio.app’s Integrated Approach

Integrio.app provides a comprehensive suite of tools and workflow automation features specifically designed to help AV integrators prevent common installation errors and ensure high-quality outcomes:

- Preventing Inaccurate Site Survey Data: Integrio’s Multimedia Site Survey Tools (Site Builder, Image Annotation, Measurements) ensure thorough and accurate data capture from the outset. This data seamlessly feeds into the design and installation planning phases, minimizing errors stemming from poor initial information.

- Improving Cable Management (through better planning): While Integrio doesn’t physically manage cables, its Product-to-Space Mapping and detailed design planning capabilities allow for better pre-installation planning of cable pathways and requirements, which can be documented for the installation team.

- Ensuring Correct Equipment Mounting/Placement: Integrio’s Product-to-Space Mapping allows for precise virtual placement of all equipment. Installation teams can access these detailed plans on-site via the mobile app, ensuring every component is installed exactly as designed.

- Accounting for Environmental Factors (in planning): During the site survey and design phase within Integrio, notes and requirements regarding lighting, acoustics, and ventilation can be meticulously documented and linked to specific areas or equipment, ensuring these are considered before installation.

- Validating Power/Network Needs (through documentation): Equipment lists and specifications managed within Integrio can be used to accurately calculate power and network requirements during the design phase, which are then communicated to relevant trades or the installation team.

- Facilitating Coordination with Other Trades: Integrio’s centralized platform and communication tools improve information sharing. Project plans, including AV-specific requirements, can be easily shared with other contractors involved in the project.

- Clarifying Design Schematics: By providing access to detailed Product-to-Space Maps and clear documentation directly on mobile devices in the field, Integrio reduces the chances of misinterpreting complex designs.

- Systematizing Testing & Commissioning: Integrio’s Workflow Automations can incorporate mandatory, detailed checklists for system testing and commissioning, ensuring every step is followed and signed off.

- Supporting Product Knowledge (via accessible documentation): Product specifications, installation guides, and training materials can be attached to project tasks or equipment items within Integrio, providing easy access for technicians.

- Promoting Correct Tool Usage (through checklists): Pre-installation checklists within Integrio workflows can include reminders or requirements for specific tools or safety gear.

- Streamlining As-Installed Documentation: Information captured throughout the project in Integrio, including any approved changes and final placements, forms the basis for accurate as-built documentation, which can be generated using the Branded Documentation features.

- Efficient Snagging & Issue Resolution: Integrio’s platform allows for easy reporting of snags (with photos/notes from the field), assignment to team members, and tracking through to resolution, all managed via automated workflows.

Building a Culture of Quality: Beyond Software

While powerful software like Integrio.app provides the framework for preventing installation errors, it’s most effective when combined with a company culture that prioritizes quality and continuous improvement:

- Invest in Training: Ensure your technicians are well-trained on new technologies, installation best practices, and the software tools you implement.

- Standardize Your Processes: Use your AV project management software to define and enforce standard operating procedures for all key installation tasks.

- Conduct Post-Project Reviews: After each project, review what went well and what didn’t. Identify any errors that occurred and update your processes or checklists to prevent them in the future.

- Empower Your Team: Encourage team members to flag potential issues early and contribute to improving processes.

Achieve Installation Excellence with Integrio

The days of accepting installation errors as an unavoidable cost of doing business are over. By understanding the common pitfalls and leveraging the power of workflow automation and integrated project management tools like Integrio.app, AV integrators can significantly reduce mistakes, improve efficiency, enhance client satisfaction, and ultimately, boost their profitability.

Don’t let the “dirty dozen” dictate the success of your AV projects. Take control with smarter processes and the right technology.

Explore Integrio.app’s features for AV Integrators and discover how you can bring unparalleled clarity to your next project.

Arrange a one-to-one demo and trial integration today free of charge.

Arrange a demo

Arrange a demo with an expert member of the team today

Further Reading

- The Ultimate Guide to AV Project Management Software

- From Chaos to Clarity: How Product-to-Space Mapping Revolutionizes Commercial AV Design & Installation

- Ditch the Clipboard: Why Multimedia Site Survey Software is a Must-Have for Modern AV Integrators